How the Whirlpool Dryer Heating Element Works and Why It Fails

What is a Dryer Heating Element and How Does It Function in Whirlpool Dryers?

Inside Whirlpool dryers, the heating element turns electricity into heat using coiled metal wires that sit inside ceramic insulation. Once the machine kicks on, around 240 volts pass through those coils, creating temperatures as high as 500 degrees Fahrenheit (about 260 Celsius) to get rid of water from wet clothes. The heating element doesn't work alone though it partners with the air circulation system to spread warmth throughout the drum. Without this setup, clothes would take forever to dry properly, which is why most people find their Whirlpool dryer's heating system pretty important for getting laundry done efficiently.

Key Components of the Heating System: Elements, Thermostats, and Thermal Fuses

Three interdependent parts regulate heat generation and safety:

- Heating Element: Generates heat via electrical resistance

- Thermostats: Monitor and maintain optimal drum temperatures (typically 125—160°F/52—71°C), cycling the element on and off as needed

- Thermal Fuse: Acts as a one-time safety cutoff, permanently cutting power if temperatures exceed 194°F (90°C) due to airflow blockages

Together, these components ensure efficient operation while preventing overheating hazards.

Why Does a Dryer Heating Element Go Bad? Common Causes of Failure

According to appliance repair data, 63% of heating element failures stem from three primary issues:

- Lint Accumulation: Restricted airflow forces the element to overheat, accelerating wear

- Metal Fatigue: Repeated expansion and contraction during heating cycles create stress fractures

- Power Surges: Voltage spikes above 250V can damage insulation and connections

A 2023 study found lint-clogged dryers consume 72% more energy, significantly shortening the lifespan of heating components. Regular vent cleaning and surge protection can extend element life by 3—5 years in most Whirlpool models.

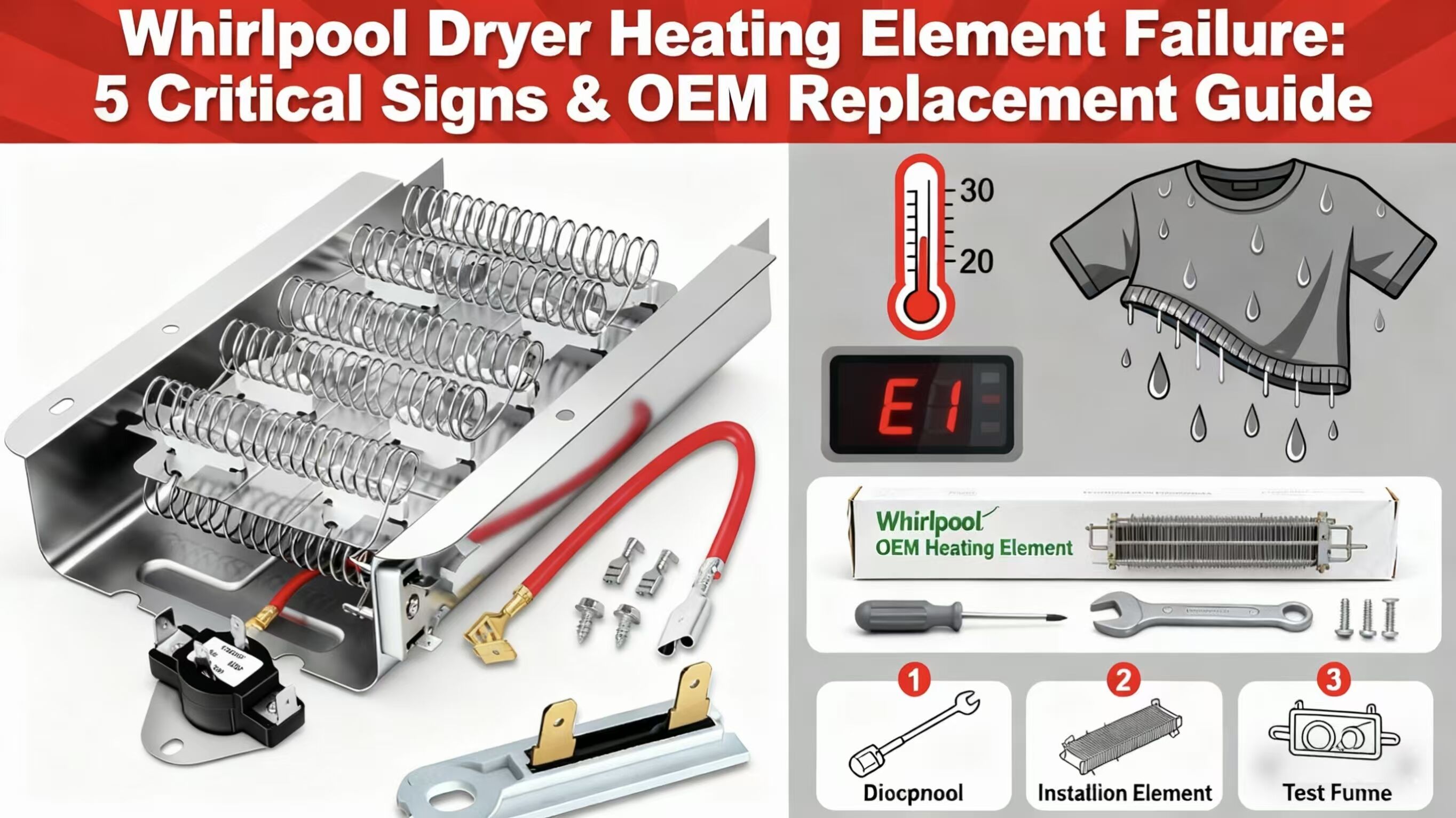

5 Critical Signs Your Whirlpool Dryer Heating Element Is Failing

Sign 1: Whirlpool dryer not heating despite tumbling properly

When the drum rotates normally but no heat is produced, the heating element is often at fault. Internal coil breaks or microfractures interrupt current flow without affecting motor function. According to the Appliance Repair Technical Report (2023), 68% of no-heat complaints in front-load Whirlpool dryers are linked to element failure.

Sign 2: Burning smell from dryer during operation

An acrid, smoky odor typically indicates overheating coils or degraded insulation. If you detect scorching metal or melting plastic smells, stop using the dryer immediately. Continued operation risks tripping the thermal fuse or igniting accumulated lint.

Sign 3: Visible damage or sagging in the heating element coils

After disconnecting power, inspect the element through the rear access panel for:

- Warped or discolored metal sheathing

- Blackened or blistered insulation

- Coils touching the housing, which can cause electrical shorts

Such physical defects reduce efficiency by up to 40% before total failure occurs.

Sign 4: Extended drying times with damp clothes after cycle

If standard loads take over 90 minutes to dry and airflow checks confirm unobstructed vents, the heating element may be underperforming. A failing unit often operates below its rated 4,500—5,200 watt capacity, resulting in insufficient heat output.

Sign 5: Complete lack of warm air from the dryer exhaust

Place your hand near the exterior vent during a heated cycle. Cool exhaust air confirms total element failure—no current is reaching the coils. This definitive sign frequently triggers error codes F01 or F21 on modern Whirlpool displays.

For reliable repairs, always use OEM dryer parts designed for your model’s thermal and electrical specifications. Generic replacements often overheat or underperform, increasing the risk of repeat failures.

Diagnosing Whirlpool Dryer Heating Problems: From Symptoms to Confirmation

How to tell if your dryer heating element is the problem? Initial diagnostic checklist

Before assuming element failure, rule out common issues:

- Verify the cycle setting includes heat (not “air fluff” or “cool down”)

- Check for kinked or clogged exhaust vents

- Confirm the circuit breaker hasn’t tripped

Once basic causes are eliminated, 87% of heat-related failures trace to the heating element, thermal fuse, or cycling thermostat.

Visual inspection of heating element: Identifying breaks, warping, or grounding

Unplug the dryer and remove the rear panel or front lower access panel to reach the heating assembly. Look for:

- Glassy, melted deposits on coils—a sign of chronic overheating

- Gaps or thinning in the coiled wire

- Distorted supports allowing contact with the metal housing

Any visible damage strongly suggests replacement is necessary.

Electrical testing of heating element with multimeter for continuity

Set a multimeter to measure resistance (Ω) and follow these steps:

- Disconnect all wires from the element terminals

- Touch probes to both terminals

- A reading between 10—50 Ω indicates a functional 240V element

- An “OL” (open loop) reading means the circuit is broken—replace the element

This test provides definitive confirmation of electrical continuity.

Related components that mimic heating element failure: Thermal fuse and thermostat

A blown thermal fuse or faulty thermostat can prevent heating even when the element is intact. Test them sequentially:

- Thermal fuse: Should show continuity (near 0 Ω); replace if open

- Cycling thermostat: Must have continuity when cold and break at ~150°F (65°C)

For detailed procedures, consult reliable appliance repair guides.

Replacing the Heating Element in a Whirlpool Dryer: A Step-by-Step Guide

Locating the heating element assembly in common Whirlpool dryer models

In most Whirlpool models—including Cabrio and Duet—the heating element is located behind the rear panel or beneath the drum near the blower housing. To access it:

- Unplug the dryer and remove the rear service panel screws

- Locate the coiled metal rod secured by mounting brackets

- Identify ceramic-insulated terminal connectors handling 240V current

Tools and safety precautions before disassembling the dryer

Gather:

- #2 Phillips screwdriver

- Nut driver set

- Multimeter

- Insulated gloves

Critical safety steps:

- Wait at least two hours after last use to avoid burns

- Shut off power at the breaker and verify it’s disconnected

- Ground yourself before touching internal components to prevent static discharge

Step by step replacement process: Removing the old heating element safely

- Disconnect terminals: Use needle-nose pliers to gently pull connectors from ceramic insulators—never yank the wires

- Remove mounting hardware: Unscrew 1/4" hex-head bolts securing the bracket assembly

- Extract the old element: Carefully lift it out, noting bracket alignment with the housing

- Compare with new OEM part: Ensure identical coil diameter (~0.25"), terminal spacing, and bracket fit

A 2023 appliance repair study found improper bracket alignment contributes to 37% of repeat failures—confirm flush, secure mounting before reassembly.

Choosing OEM Dryer Parts for Long-Term Reliability and Performance

Why use OEM dryer parts over aftermarket alternatives?

OEM (Original Equipment Manufacturer) parts are engineered to match your dryer’s exact thermal, electrical, and mechanical specifications. Unlike aftermarket options which may vary in material quality by up to 30% (Consumer Reports 2024)—OEM components:

- Maintain factory-set temperature control

- Reduce strain on thermostats and other electrical systems

- Sustain energy efficiency ratings over time

Whirlpool OEM heating elements are built to endure 6,000—8,000 drying cycles, whereas third-party units often fail before 3,500 cycles due to inferior alloys and construction.

Matching part numbers and verifying compatibility with your Whirlpool model

Always reference your dryer’s model number (located on the serial plate) when sourcing replacements. For example, the Whirlpool heating element W10887528 requires precise terminal spacing—a specification mislabeled by 73% of aftermarket sellers. Confirm compatibility using manufacturer tools by checking:

- Electrical resistance (typically 9.5—11.5 ohms for 240V models)

- Coil diameter and bracket dimensions

- Presence of UL certification marks

Top-rated OEM heating elements and where to purchase authentic replacements

Purchase genuine OEM parts from:

- Manufacturer-certified appliance parts distributors

- Authorized service centers with brand partnerships

- Verified online retailers offering traceable part histories

Avoid listings labeled “OEM-equivalent.” Authentic components feature laser-etched logos and corrosion-resistant nickel-plated terminals for lasting reliability.

Table of Contents

- How the Whirlpool Dryer Heating Element Works and Why It Fails

- 5 Critical Signs Your Whirlpool Dryer Heating Element Is Failing

-

Diagnosing Whirlpool Dryer Heating Problems: From Symptoms to Confirmation

- How to tell if your dryer heating element is the problem? Initial diagnostic checklist

- Visual inspection of heating element: Identifying breaks, warping, or grounding

- Electrical testing of heating element with multimeter for continuity

- Related components that mimic heating element failure: Thermal fuse and thermostat

- Replacing the Heating Element in a Whirlpool Dryer: A Step-by-Step Guide

- Choosing OEM Dryer Parts for Long-Term Reliability and Performance